Coatings

Structural Coating

Surface preparation is the essential first stage treatment of a steel substrate before the application of any coating, and is generally accepted as being the most important factor affecting the total success of a corrosion protection system.

The performance of a coating is significantly influenced by its ability to adhere properly to the substrate material. Residual mill scale on steel surfaces is an unsatisfactory base to apply modern, high performance protective coatings and is therefore removed by abrasive blast cleaning. Other surface contaminants on the rolled steel surface, such as oil and grease are also undesirable and must be removed before the blast cleaning process.

The surface preparation process not only cleans the steel, but also introduces a suitable profile to receive the protective coating.

Paint specifications usually comprise a sequential coating application of aints or alternatively paints applied over metal coatings to form a ‘duplex’ coating system. The protective paint systems usually consist of primer, undercoat(s) and finish coats. Each coating ‘layer’ in any protective system has a specific function, and the different types are applied in a particular sequence of primer followed by intermediate / build coats in the shop, and finally the finish or top coat either in the shop or on site.

We enable contractors to provide ‘best value’ service to maximize coating performance over structure life and to reduce whole life costs. high quality replica rolex watches

mirror watch replica fake vintage rolex replica

rolex submariner replica price

SEND AN EMAIL AND GET YOUR QUOTATION WITHIN ONE BUSINESS DAY.

Coatings

Structural Coating

Intumescent Coating

Aess Coating

Marine Coating

Pipe Coating

Vessels Coating

Oil Tank Coating

Cementitious Coating

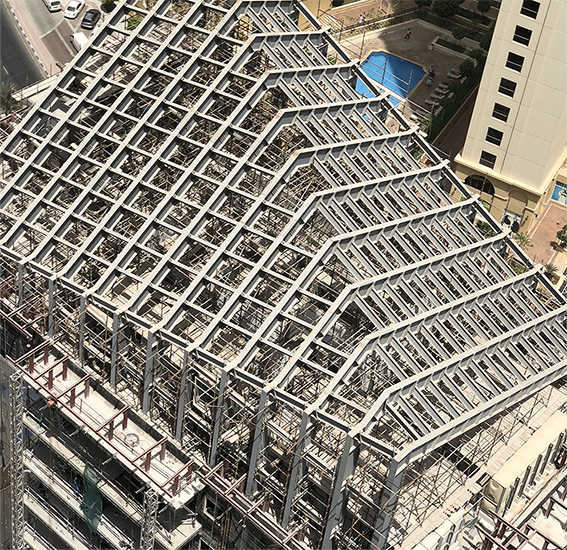

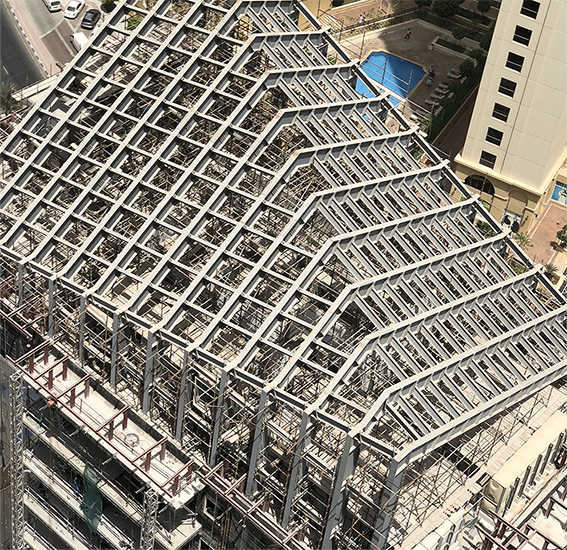

Project Gallery

Our Featured Projects

Our SERVICE

What We Do

Get a Quote

Get a Quote Form

Contact Us

Contact with us